Key Takeaways: At a Glance

- The Reality: Feed accounts for 70–85% of poultry production costs.

- The Problem: Most farms treat feed as a fixed number, not a daily decision.

- The Risk: Overfeeding or underfeeding compounds quietly into major losses.

- The Shift: Feed must be managed with daily, local intelligence.

- The Future: Poultry intelligence begins with feed intelligence.

If you ask any poultry farmer where most of their money goes, the answer is immediate.

Feed.

In most African poultry operations, feed accounts for 70 to 85 percent of total production costs. No other input comes close. Housing, labor, vaccines, electricity, and logistics all matter. But feed largely determines whether a farm survives or struggles.

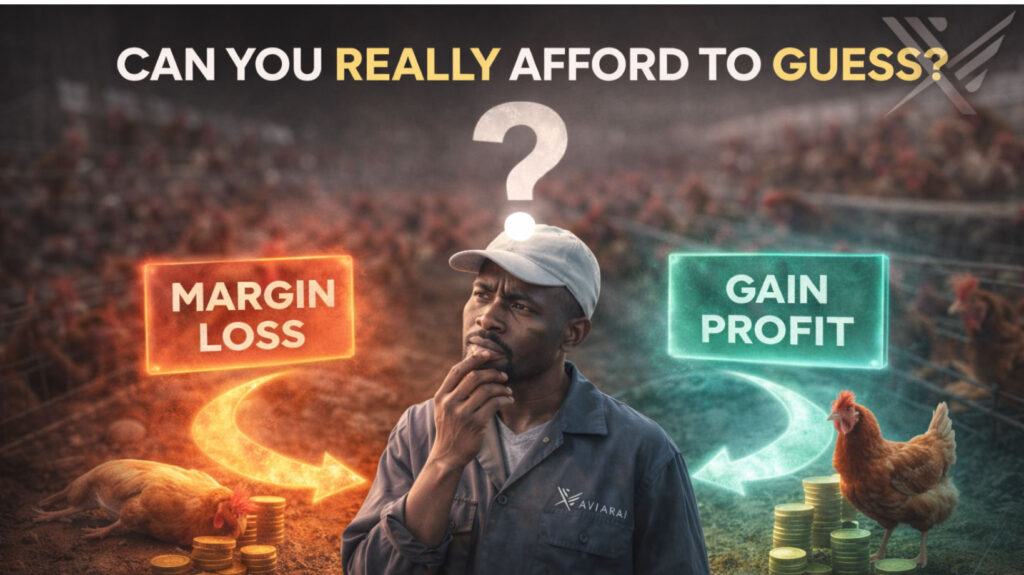

Yet despite this reality, feed decisions are often made with the least precision. This contradiction sits quietly at the heart of poultry farming across the continent.

This pattern is part of a broader problem we explored in This One Error Is Costing African Poultry Farmers Billions; how reliance on guesswork instead of intelligence quietly erodes farm margins.

Feed Is Treated as a Fixed Amount. It Is Not.

On many farms, feeding follows a familiar routine.

A fixed grams-per-bird-per-day target.

A standard feeding curve from a foreign manual.

An adjustment only when something looks obviously wrong.

These practices feel safe because they are common.

They feel safe because they come from breed producers.

They are also expensive.

Feed is not a fixed amount.

Feed is a daily decision.

Every day, birds respond differently based on temperature, age, health status, feed quality, stress, and housing conditions. Yet feeding levels often remain unchanged for weeks or months at a time.

Imagine feeding commercial layers 115 grams per day from 28 weeks until end of lay.

A few extra grams per bird does not seem like a big deal. But across thousands of birds, day after day, it quietly compounds.

A 5,000-layer farm feeding just 2 grams more than needed per bird per day can lose thousands of dollars over a single production cycle without seeing any improvement in egg output.

A farm feeding an average of 8 grams more than needed lost $2,500 within 97 days.

The loss does not show up as a crisis.

It shows up as margins that never quite meet expectations.

Uniform Feeding Guidelines Do Not Match African Reality

Most feeding guidelines used across Africa were developed under very different conditions.

Climate-controlled housing.

Consistent ingredient quality.

Highly automated systems.

African poultry farms rarely operate under these conditions.

Maize quality varies widely between suppliers and seasons.

Soybean meal protein levels fluctuate.

Heat stress can sharply reduce feed intake in one region while another remains unaffected.

Even neighboring farms using the same feed may experience different outcomes.

Yet feeding guidelines remain uniform.

And many of those guidelines are imported.

A farmer in Ibadan, another in Jos, and another in Aba may all feed the same grams per bird despite facing entirely different realities.

The result is predictable.

Some farms overfeed and waste money.

Others underfeed and suppress production.

Most have no clear way to tell which situation they are in.

Sudden Feed Changes Are Risky. No Changes Are Also Risky.

There is a reason physicians taper certain medications.

When farmers do adjust feed, it is often reactive.

Egg production drops, so feed is cut sharply to save cost.

Output dips, so feed is suddenly increased in hopes of recovery.

Both actions carry risk.

Sudden feed reductions can stress birds, reduce egg size, and create longer-term production losses. Sudden increases can raise costs without delivering results.

Because the effects of feed changes are not immediate, farmers are often left guessing whether an adjustment helped or harmed.

This is why many farms avoid changes altogether.

Staying the course feels safer than experimenting.

But doing nothing is still a decision.

And in a volatile environment, it is often the most expensive one.

Feed Decisions Are Made Daily. Intelligence Is Not.

Here is the uncomfortable truth.

Farmers make feed decisions every day.

But they make them without daily local intelligence.

They know how much feed went in yesterday.

They know how many eggs came out.

They do not know whether today’s feeding level is optimal.

Without context, yesterday’s numbers do not answer today’s question.

The problem is not a lack of discipline.

The problem is that the system does not translate daily records into clear signals.

Feed is too important to be managed by averages, rules of thumb, or once-a-month reviews.

Feed is too important to be managed by guidelines developed across oceans.

The Future of Poultry Farming Will Start With Feed Intelligence

If African poultry farming is going to move beyond guesswork, it will start with feed.

Not robots.

Not software.

Not hardware.

Not automation.

Not imported tech.

It will start with understanding, day by day, how feed interacts with production, cost, and bird health under local conditions.

Precision in feeding does not mean dramatic changes.

It means gradual, informed adjustments guided by evidence, not fear.

In the coming weeks, we will explore why most existing tools fail to deliver this level of insight, and what it means to manage feed as a living system rather than a fixed line item.

Because when 70 percent of your cost is decided daily, guessing is no longer an option.